Top-Rated Mold Design Services in Houston

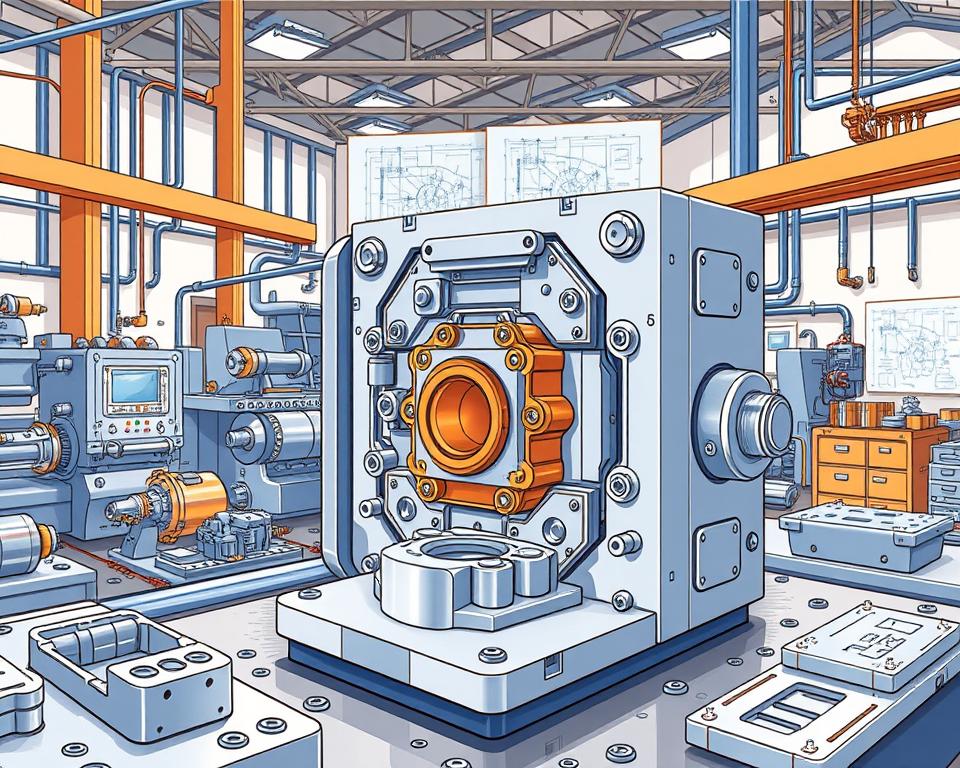

By 2025, the global injection molded plastics market will reach $440 billion. Such expansion highlights why expert mold design is essential. They develop precision mold designs tailored to varied industries. In Houston, Lowrance Machine is a leading mold design company. They provide cutting-edge mold solutions for the automotive, aerospace, and consumer-goods markets.

Lowrance Machine uses advanced technologies like CAD software and 3D printing. Their team ensures precision and efficiency in the molding process. Their seasoned experience and engineering prowess make them a dependable collaborator. Learn how their mold design Houston capabilities improve your initiatives and align with modern market requirements.

The Critical Role of Mold Design Services

Mold design services are vital in the manufacturing world, affecting product quality and operational efficiency. Effective mold design underpins both product function and lifespan. Companies that invest in expert mold design can cut production costs and improve quality standards.

Lowrance Machine showcases the value of working with seasoned professionals. They engage closely with clients to develop tailored designs. By employing cutting-edge methods like 3D modeling and CAD, they help businesses create molds that adhere to high standards.

Opting for premier mold design services elevates product functionality and powers business growth. With optimized mold design, manufacturing runs smoothly and firms gain market advantage.

Mold Design Houston: Types of Services Offered

Lowrance Machine offers a wide range of mold design Houston services, tailored to meet specific industry needs. Understanding each mold service type guides firms to the perfect choice for their tasks. Key categories include:

- Custom Design Solutions: Personalized mold design services built around specific demands.

- Test Mold Creation: Early-stage mold prototyping to validate designs.

- Houston Injection Mold Services: Precision-engineered injection molds built to last.

- Advanced 3D Design: Advanced CAD to develop exact 3D mold prototypes.

- Maintenance Services: Repair and upkeep solutions to maximize mold longevity.

These services collectively enhance throughput, raise quality, and cut expenses. By understanding the available mold services, industries can better meet their manufacturing needs.

Why Hire Professional Mold Designers

Partnering with seasoned mold designers yields multiple manufacturing benefits. These benefits include enhanced accuracy, durability, and efficiency. Bespoke design drives superior product standards and uniformity.

Seasoned teams provide critical workflow enhancements. They certify molds comply with both generic and custom criteria. Working together drives creative solutions and lengthens product durability.

Economical operations are a key perk. Advanced technology and methodologies reduce wastage and minimize delays. These improvements lead to better budgets and healthier profit margins. Timely design execution also enables quicker market entry, giving businesses a competitive edge.

In summary, specialized mold design companies provide critical support for manufacturers. They dedicate themselves to streamlining operations and enriching output.

Next-Gen Mold Design Innovations

Innovation has driven monumental shifts in mold design. Lowrance Machine leads the way with its cutting-edge mold design techniques. These methods enhance throughput and refine product excellence. Modern engineering tools expedite custom mold fabrication and lower overheads.

Additive manufacturing shines by producing fast prototypes and intricate shapes. It significantly reduces material waste compared to traditional methods. Virtual simulation tools let engineers validate and optimize molds digitally for better accuracy and speed.

In Houston, mold design experts are embracing these modern strategies. Firms achieve market edge through digital design and high-tech manufacturing. They facilitate flexible, rapid-response mold development to satisfy diverse applications.

| Technique | Description | Benefits |

|---|---|---|

| Additive Manufacturing | Employs layer-by-layer building for quick mold production. | Accelerates turnaround and minimizes waste. |

| Virtual Testing Tools | Enables digital prototype testing and refinement. | Enhances accuracy and optimizes performance. |

| CAD Platforms | Leverages CAD for detailed mold engineering. | Supports bespoke specifications and rapid revisions. |

To Summarize

Professional mold design underpins both efficient operations and quality products in Houston. They provide the technical skill needed for complex mold projects. They tailor solutions to individual requirements for optimal results.

As a leader in accuracy and client partnership, Lowrance Machine stands out. Bespoke molds and innovative methods from professionals maintain market leadership. Partnering with specialists enhances output and optimizes workflows.

Opting for professional mold design in Houston balances high standards with operational efficiency. Businesses can meet customer expectations effectively and gain a significant competitive advantage. Leveraging professional mold design is crucial for success in a crowded industry.